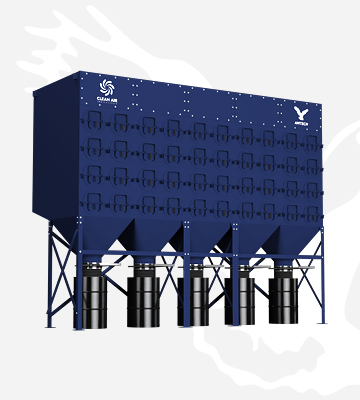

Amtech Dust Collection Series by Clean Air Industries

-

Call Us Today

+1 (866) 665-1829

-

Business Hours (ET)

Mon - Fri: 8 am to 5 pm

-

7 Superior Drive

Rome, GA 30161

Downdraft Tables

That Can't Be Beat

Discover the Defender Downdraft Table Series by Clean Air Industries, featuring best in-class performance.

LEARN MOREPowerful

Fume Extraction

Eliminate toxic welding fumes at the source with the Clean Air Industries P1200 Portable Weld Fume Extractor.

LEARN MORE

Unleash the Power of Clean Air

Product Overview

Experience top-tier dust collection technology, designed for both fine and abrasive particulates. The key challenge: re-entrainment, where filtered dust is stirred up before settling. Our solution? Efficiently remove dust from the filter, ensuring it collects in the hopper without recontamination.

The Amtech ATV Vertical Cartridge Collector Series by Clean Air Industries features our patented downflow design that minimizes re-entrainment and extends filter life. Controlled inlet air velocity ensures downward airflow, preventing disturbance below the filters for efficient cleaning during both operation and shutdown. Models range from 8 to 128 cartridges with up to 40,500 CFM of airflow.

REQUEST A QUOTE

Why Choose Amtech ATV Vertical Cartridge Collectors?

The system’s precise control of inlet air velocity ensures strict downward airflow, preventing disruptive movements and keeping the area below the filters undisturbed for efficient cleaning during operation and shutdown. Trust Clean Air Industries for reliable dust collection, promoting a cleaner, safer environment.

-

Zero Velocity Design

Our unique structure ensures no movement at the base of each filter stack. This lets the dust settle freely below the cartridges, eliminating re-entrainment.

-

Dual Dust Management

Our design directs larger dust particles to the settling area, while fine particles are effectively captured by the filters for optimal dust collection efficiency.

-

Venturi Reverse Pulse Cleaning

Boost cleaning efficiency with our quick pressure release system, delivering a uniform burst of compressed air across the filter for superior results over traditional methods.

-

Pulse Jet Performance

We’ve fine-tuned the orifice size and position to ensure maximum performance and cost-effectiveness. Plus, choose from four jet pulse cleaning initiation methods to perfectly suit your application.

Additional Product Details

Recommended Applications

• Manual Welding

• Robotic Welding

• Print Milling (water-based & synthetic coolants)

• Plasma Cutting

• Laser Cutting

• Metal Grinding

• Designed for 24/7 operations

Product Benefits

• Effectively eliminates harmful dust and fumes from your environment

• Designed to work 24/7 even in high demand applications

• Clean Air Industries offers turn-key installation

• Main filter life exceeds the industry standard

• Fully compliant with OSHA regulations

• American made with quick service and support when required

• Rugged construction designed for high performance and heavy duty use

Standard Features

• Carbon Steel Welded Construction 7 ga./11 ga.

• Base Unit Includes Collector, Legs, Hopper & Turbo Pulse Control

• 55 Gallon Dust Drum & 14″ Drum Lid Kits

• Compressed Air Reverse Jet Pulse, Dual1.5″ Valves with Manifolds

• Ground Mount Backward Inclined Blower Class III & IV Construction, Balanced & Tested, 16,000 cfm @ 11” WG / 65,000 cfm @ 16” WG

• Variable Frequency Drive NEMA 12 & NEMA 1 or Magnetic Motor Starter

• AT-PC Turbo Digital Pulse Control & Cycle Down

Optional Features

• Models Ranging From 8 to 128 Cartridges

• Washable 100% Spunbond Polyester Filters

• Filter Media Fire Retardant Nanofiber, Media Efficiency 99.8% @ 0.3 Micron

• Filter Removal Single Movement Access Handle For Quick Replacement

• Side and Abrasive Inlets Designed for Fine or Abrasive Particulate

• ATV ILC Silencers for Sound Attenuation

• ATV Explosion Vents

• Fire Suppression Sprinkler Head(s) with Coupling (165°F) 1/2” NPT

• Handrails, Safety Gate & Bar Grate for Security

• Afterfilters

• Dust Trays

Technical Specifications

| Model | Motor | CFM | Weight | Width | Height | Depth |

|---|---|---|---|---|---|---|

| Amtech ATV-8 | 5 HP - 15 HP | 2000 - 4000 | 2500 lbs | 76.13" | 156.38" | 49.25" |

| Amtech ATV-12 | 7.5 HP - 25 HP | 3000 - 6000 | 3250 lbs | 93.13" | 163.88" | 49.25" |

| Amtech ATV-18 | 10 HP - 40 HP | 4500 - 9000 | 4000 lbs | 96.88" | 179.5" | 69.25" |

| Amtech ATV-24 | 15 HP - 50 HP | 6000 - 12000 | 5000 lbs | 113.63" | 188.88" | 70.25" |

| Amtech ATV-32 | 20 HP - 50 HP | 8000 - 16000 | 5500 lbs | 115.88" | 202.25" | 90.25" |

| Amtech ATV-40 | 25 HP - 60 HP | 10000 - 20000 | 6000 lbs | 110.25" | 188.63" | 96.38" |

| Amtech ATV-48 | 30 HP - 75 HP | 12000 - 24000 | 6300 lbs | 130.25" | 189.75" | 96.38" |

| Amtech ATV-56 | 40 HP - 100 HP | 14250 - 28500 | 7000 lbs | 150.25" | 194.75" | 96.38" |

| Amtech ATV-64 | 50 HP - 100 HP | 16250 - 32500 | 7750 lbs | 170.25" | 203.38" | 96.38" |

| Amtech ATV-72 | 50 HP - 100 HP | 18250 - 36500 | 8500 lbs | 190.25" | 189.75" | 96.38" |

| Amtech ATV-80 | 60 HP - 100 HP | 20250 - 40500 | 9000 lbs | 210.25" | 191.75" | 96.38" |

| Amtech ATV-96 | 60 HP - 150 HP | 24000 - 48000 | 12600 lbs | 260.6" | 189.75" | 96.38" |

| Amtech ATV-112 | 80 HP - 200 HP | 28500 - 57000 | 14000 lbs | 300.6" | 194.75" | 96.38" |

| Amtech ATV-128 | 100 HP - 200 HP | 32500 - 65000 | 15500 lbs | 340.6" | 203.75" | 96.38" |

Related Products

Request A Quote

Our air cleaning experts are happy to assist with your project - no matter how big or small! Please provide the information requested below so we can help you find the right solution for your needs.

* Mandatory form field.