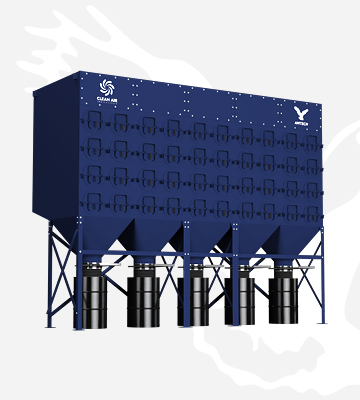

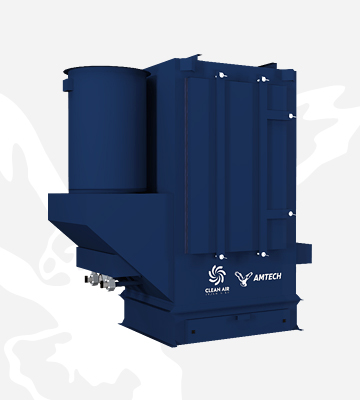

Amtech Dust Collection Series by Clean Air Industries

Preloader Close

-

Call Us Today

+1 (866) 665-1829

-

Business Hours (ET)

Mon - Fri: 8 am to 5 pm

-

7 Superior Drive

Rome, GA 30161